Advantages of metal stamping parts:

Metal stamping parts are mainly applied to plates, village materials, etc. by punching machines and molds, so that they are deformed and separated to obtain the metal stamping parts we want. Compared with castings and forgings, metal stamping parts are thin, uniform, light and strong. Etc.

Metal stamping parts can produce stamping parts with ribs, ribs, undulations or flanging that are difficult to manufacture by other methods to improve their strength and toughness. If precision molds are used, the precision of the workpiece can reach the micron level, and the repeatability is high. Specifications Consistent, can punch out holes, bosses, etc.

If a multi-station continuous mold is used, it can generally produce hundreds of pieces per minute, and complete the processes of feeding, stamping, output, and waste discharge in a short period of time. Metal stamping parts generally no longer undergo cutting processing, or only need a small amount of cutting. processing.

The advantages of metal stamping parts are far more than the above points. The above are the more prominent advantages. There are reasons why metal stamping parts can be widely used.

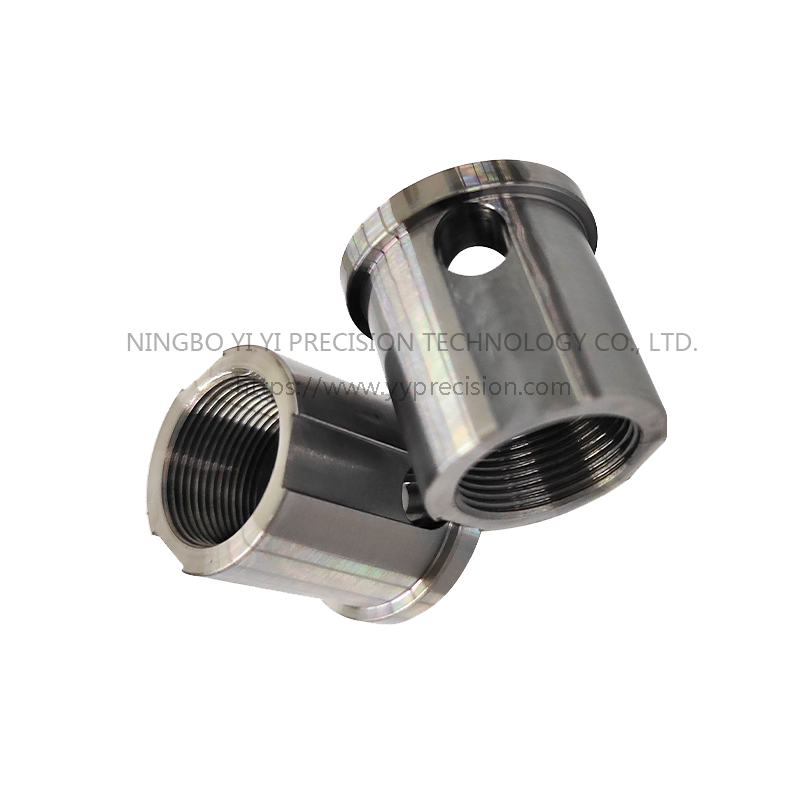

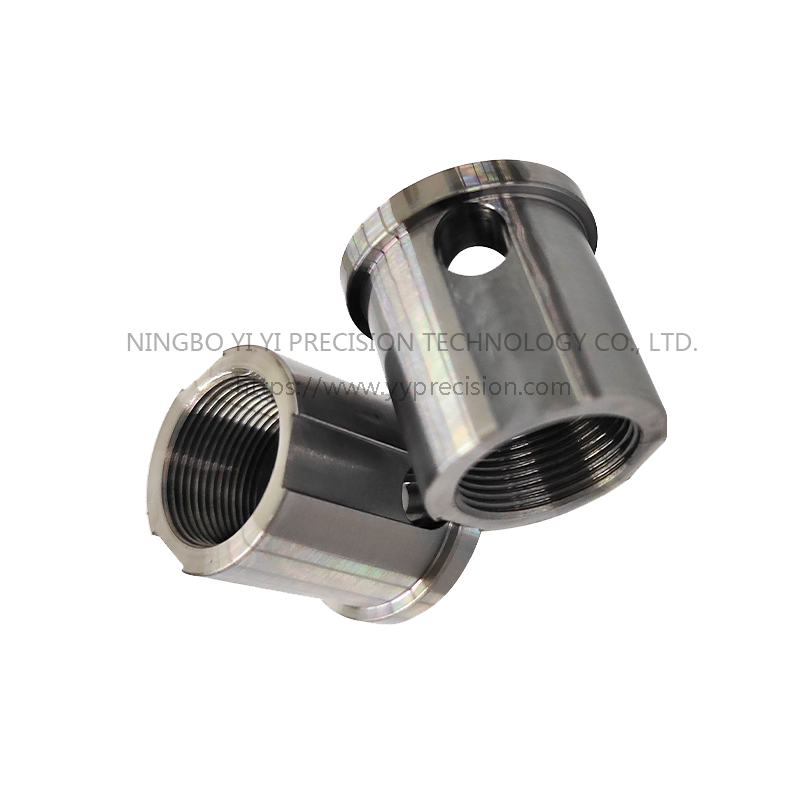

Car Tire Quick Inflation Joint Body

Material:1215

Size:Od 22*Length 20.6

Weight:12g

Thread Size:9/16-32UNS

Color:Galvanized