Die casting is a manufacturing process that has been around for over a century. It involves melting a metal and then injecting it into a die to create a part. The die is a specially designed mold that is shaped like the desired part. Once the metal cools and solidifies, the die is opened, and the part is ejected. Die casting is a highly precise and efficient process that is used to create complex metal parts for a wide range of industries, including automotive, aerospace, and medical.

One of the key benefits of die casting is its ability to produce highly precise parts. Because the metal is injected into a mold, the resulting part has an exact shape and size. This level of precision is difficult to achieve with other manufacturing processes, such as forging or machining, which rely on cutting or shaping the material after it has been formed.

Another advantage of die casting is its ability to produce parts with a high level of consistency. Because the process is highly automated, each part that is produced is nearly identical to the next. This makes die casting an ideal choice for high-volume manufacturing, where consistency and efficiency are critical.

Die casting can be used to create a wide range of parts, from small components to large, complex structures. Some of the most common die cast parts include engine blocks, transmission cases, and aerospace components. These parts are used in a variety of applications, from automobiles and airplanes to medical equipment and industrial machinery.

To achieve the highest level of precision in die casting, several factors must be taken into account. First, the design of the die must be carefully crafted to ensure that the resulting part has the desired shape and dimensions. This requires a deep understanding of the material being used, as well as the manufacturing process itself.

Next, the metal used in the die casting process must be carefully selected and prepared. Different metals have different properties, and the choice of metal will impact the final properties of the part. For example, aluminum is a popular choice for die casting because it is lightweight and has good corrosion resistance.

Finally, the manufacturing process itself must be carefully controlled to ensure that each part is produced with a high level of precision. This includes controlling the temperature of the metal, the speed at which it is injected into the die, and the cooling rate of the part. Each of these factors can impact the final properties of the part, and must be carefully controlled to achieve the desired results.

In conclusion, die casting is a highly precise and efficient manufacturing process that is used to create complex metal parts for a wide range of industries. Its ability to produce highly precise and consistent parts makes it an ideal choice for high-volume manufacturing. To achieve the highest level of precision in die casting, careful attention must be paid to the design of the die, the choice of metal, and the manufacturing process itself. With the right approach, die casting can be used to create parts that are not only precise but also durable, reliable, and cost-effective.

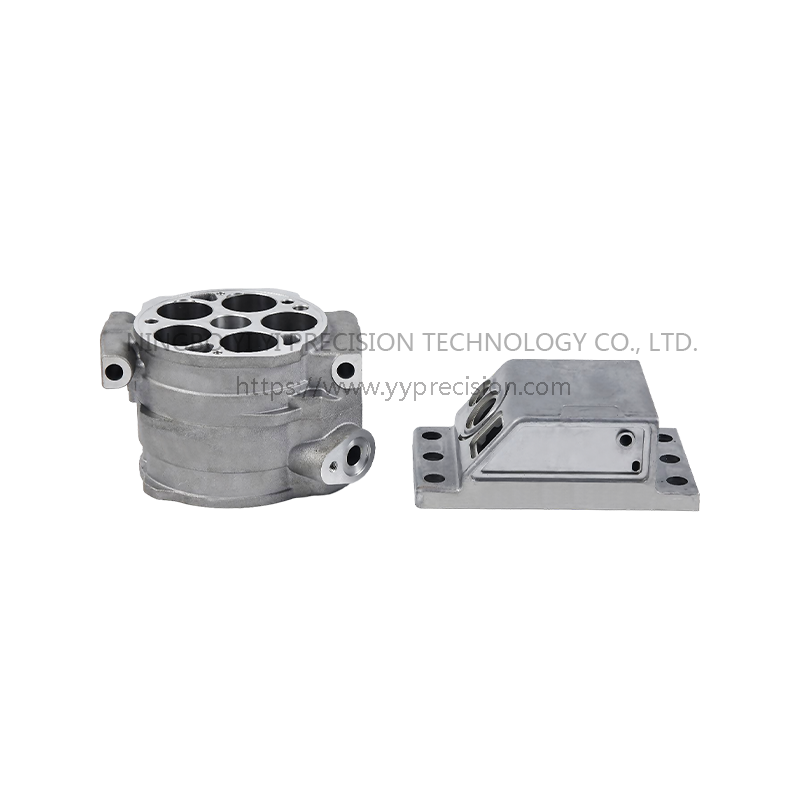

Reducer Housing To Reduce Weight

Use The Mold To Manufacture Complex Shapes, Reduce The Overall Weight Of The Product, And Use Machining To Ensure The Shape And Position Tolerance.

Material: A380

Weight: 500g