In today's modern manufacturing industry,

Stainless Steel Turning Parts play a vital role. Its corrosion-resistant, strong and durable properties make it one of the preferred materials in various industries.

The primary reason why stainless steel turned parts are widely used in many industries is its excellent corrosion resistance. The oxide film formed by its high chromium content effectively resists the erosion of most chemical media, including water vapor, oxygen, acid, alkali, etc., allowing it to maintain good performance and appearance in harsh working environments. This property makes stainless steel turned parts ideal for long-term use in many industries.

In addition to their excellent corrosion resistance, stainless steel turned parts are also known for their exceptional robustness and durability. Its high strength and excellent toughness make stainless steel parts less likely to deform or break when subjected to mechanical impact or extrusion, maintaining the structural integrity and stability of the parts. This feature is particularly important in many industries, especially automotive manufacturing, aerospace and other fields that have extremely high performance requirements for components.

Stainless steel turned parts are widely used in many industries due to their excellent performance. In the automotive manufacturing industry, stainless steel turned parts are commonly used in the manufacturing of key components such as brake systems, exhaust pipes, and engine components. In the aerospace field, due to the strict requirements on material properties, stainless steel turned parts are widely used in the manufacturing of aircraft engines, hatches and other components. In addition, in fields such as medical equipment and food processing, stainless steel turned parts are also favored for their good hygienic properties and corrosion resistance.

With the continuous development and advancement of manufacturing technology, the manufacturing process of

stainless steel turned parts is also constantly optimized. The application of CNC lathes greatly improves processing accuracy and efficiency, while reducing the impact of human factors on product quality. New cutting tools, machining fluids, etc. also make the processing of stainless steel turned parts more efficient and precise.

Stainless Steel Turning Parts have become an indispensable and important part of modern manufacturing due to their corrosion resistance, durability and wide application in various industries. It plays an important role in improving product quality and ensuring production safety, providing strong support for the development and progress of various industries.

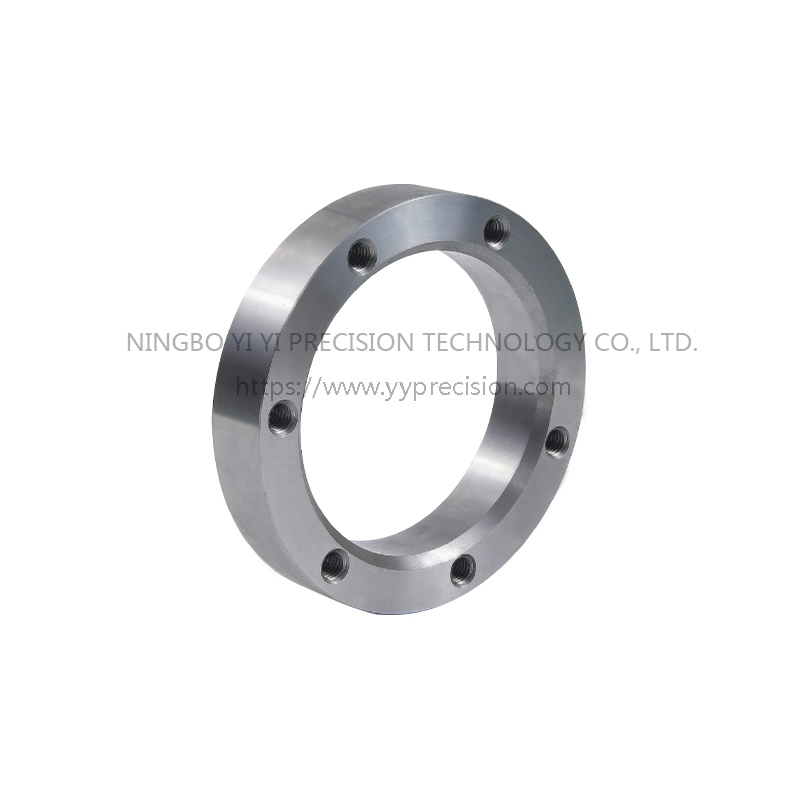

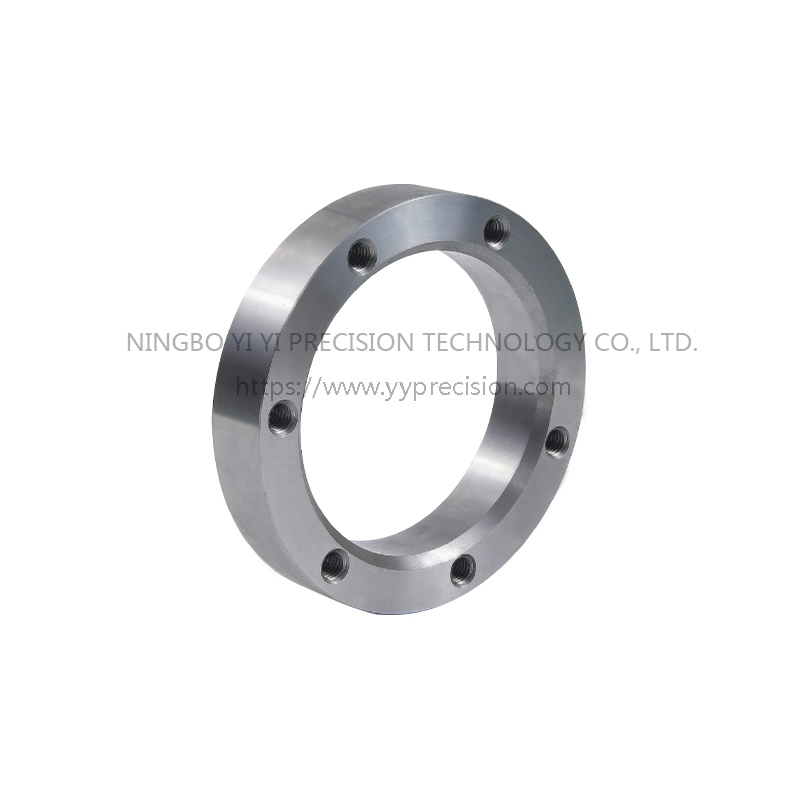

MEDIUM CARBON STEEL TURNED PARTS

MEDIUM CARBON STEEL TURNED PARTSMaterial: 45#

End Thread: M2.5

Size: OD 100mm*Thickness 25mm

Weight: 350g

Thread Size: M5