Stainless steel turned parts are a reliable and time-saving component for production process. They are highly resistant to wear and tear and are a good choice for long-term use. These components are manufactured under strict specifications and tolerances. The result is a product with an attractive appearance. In addition, they are made of high-quality materials and are durable, making them a good choice for a wide range of applications.

Precision turning components are designed to ensure that your equipment and machinery are functioning properly. These components are manufactured from a variety of materials, including aluminum, copper, and stainless steel. Each material offers unique characteristics. While choosing the right material, keep in mind that it is also important to choose a cutting tool that will work well with your material.

Precision turning parts are produced with CNC tools, which help hold the material in place while the part is rotating. This reduces costs, and also eliminates human error. Another benefit is that precision turning components are produced under tight tolerances, which are essential for the quality and functionality of your equipment.

Stainless steel turns have an attractive appearance. A number of stainless steel finishes are available, from bright mirror-like finishes to slightly reflective finishes. Choosing the right type of finish for your stainless steel turned part is essential.

Stainless steel is a durable material that is resistant to heat, water, and other substances. It is used in a wide variety of applications, from marine equipment to food processing. It can be polished to give a high-tech look. For optimal corrosion resistance, choose a stainless steel with at least ten percent chromium. However, chromium is not the only alloying element that helps prevent iron from rusting. Also, molybdenum contributes to the stainless steel's excellent corrosion resistance.

Stainless steel turned parts are often used in automobile and aerospace industries. The material can be processed to produce parts with higher strength than other metals. Additionally, it can withstand temperatures as high as 300 degrees Celsius.

There are different types of stainless steel, with several of them having a three-digit designation. Some of the most common are SUS316, SUS316L, and 18/8. Other types include A380, HPb62, and 4140. All are durable and resistant to corrosive solutions, making them useful for a wide variety of applications.

Stainless steel turned parts can be manufactured using a variety of processes, including drilling, lathing, and grinding. However, CNC turning is the most common way of producing precision turning components. Using a CNC system, the elements are positioned in appropriate directions, and a cnc computer program interprets digital information.

Precision turning components can be found in a wide variety of industries, from automobile to medical equipment. In fact, stainless steel is one of the most widely used materials for this type of machining. Although the material is strong and durable, it is not easy to machine. Since it tends to warp, machining tools must be resistant.

Stainless steel is a durable, recyclable material that can be molded to create a variety of shapes. Unlike other metals, stainless steel is not prone to rusting, and is a great choice for a wide range of products.

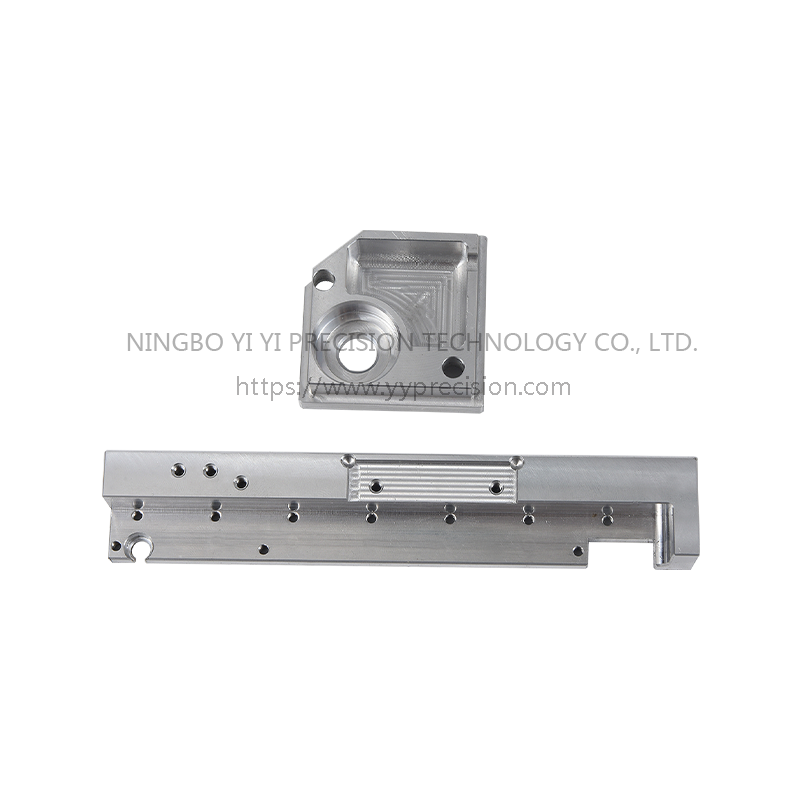

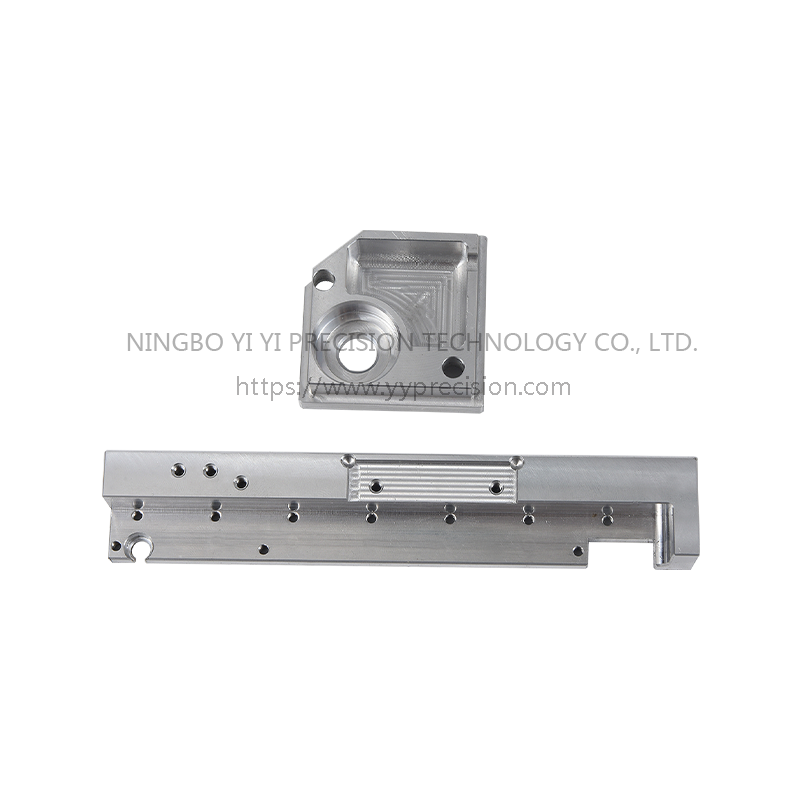

CNC Machining Of Motor Covers For Assembly Parts In The Automotive Industry

15 Threaded Holes In One Go On CNC Machine

Material: 7075

Length: 185mm

Color: Natural

Outer Diameter: 45mm

Thickness: 25mm