In the elaborate global of precision production, in which the demand for accuracy and reliability is paramount,

Stainless Steel Turning Parts play a pivotal position in shaping excellence. This advanced machining manner includes the transformation of uncooked chrome steel materials into finely crafted components, showcasing the fusion of contemporary generation and meticulous craftsmanship.

At the heart of precision production, Stainless Steel Turning Parts demonstrates its prowess with the aid of turning in components with tight tolerances and impeccable surface finishes. The process entails rotating a workpiece on a lathe whilst a reducing tool gets rid of extra fabric, resulting in elements that meet the precise specs required for a extensive range of programs. From aerospace components to clinical devices, the precision done thru stainless-steel turning guarantees that every piece meets the stringent standards demanded by means of present day industries.

One of the important thing blessings of

Stainless Steel Turning Parts lies within the fabric itself. Stainless metallic, recognized for its superb electricity, corrosion resistance, and durability, gives a foundation for components that can resist the most harsh environments. This makes it a super preference for critical applications wherein reliability is non-negotiable. The turning system lets in manufacturers to form stainless-steel into tricky forms, optimizing its houses for specific functions, and making sure the toughness and overall performance of the very last product.

In addition to its mechanical residences, stainless steel turning gives versatility in design. Manufacturers can create complex geometries and tailored shapes with ease, enabling the production of pretty specialized additives. This adaptability is mainly crucial in industries along with car engineering, where custom components are regularly required to meet the evolving needs of innovation and performance.

The synergy among generation and ability is obvious for the duration of the stainless-steel turning system. Computer Numerical Control (CNC) machines, equipped with advanced programming, guide the slicing equipment with remarkable precision. This degree of automation not simplest enhances accuracy but additionally lets in for green mass production of components, meeting the demands of massive-scale production with out compromising first-rate.

The function of stainless steel delivering precision manufacturing is synonymous with shaping excellence. As industries continue to push the bounds of innovation, the ability to provide finely crafted additives with amazing precision turns into more and more vital. Stainless metallic turning stands as a testament to the wedding of material energy, technological sophistication, and skilled craftsmanship, making sure that the products of precision manufacturing meet the best requirements of satisfactory and reliability in the pursuit of excellence.

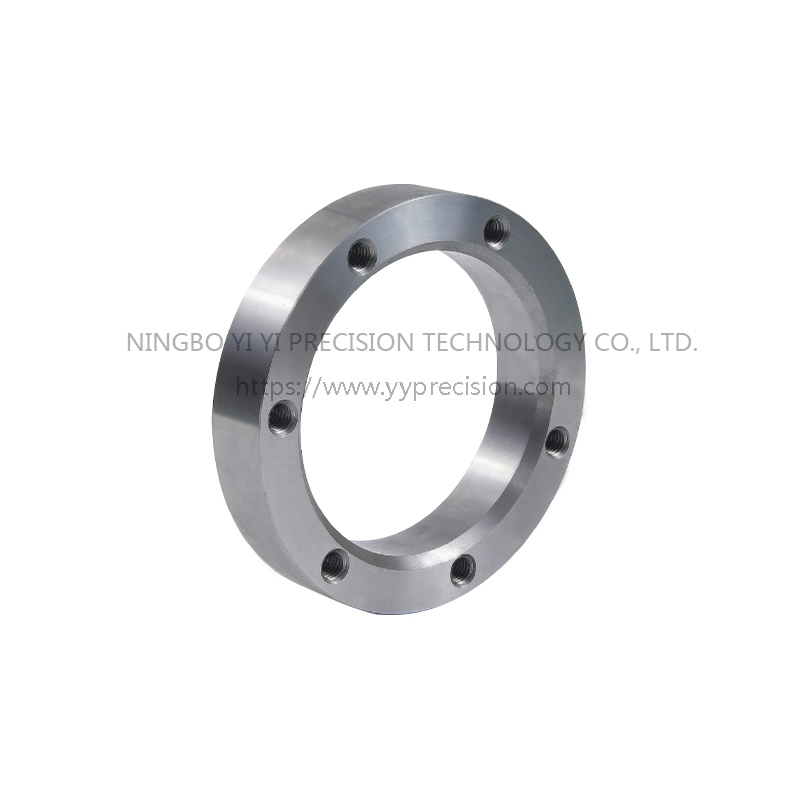

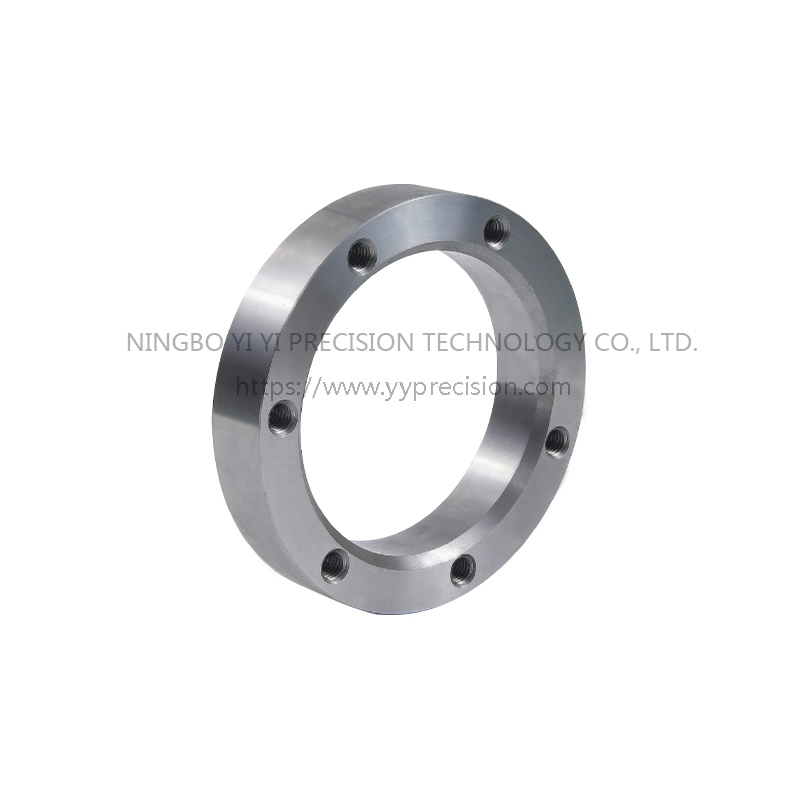

MEDIUM CARBON STEEL TURNED PARTS

MEDIUM CARBON STEEL TURNED PARTS

Medium Carbon Steel Turned Parts With Threaded End Holes

CNC Lathe Processing. First, Use A U Drill To Make Holes, Then Use A Tungsten-Carbide Boring Cutter With R0.4 Corner To Drill Internal Holes, Then Use A Tungsten-Carbide Boring Cutter With R0.2 Corner To Finish Internal Holes, Then Use A Cylindrical Cutter With 55°R0.2 Corner To Process The End Face And The Outer Diameter, Finally Cut Off, And Then Use CNC Machining Center, A Flat Cutter To Process The Plane, A D5.0 * 90° Center Drill To Center, A Tungsten-Carbide Twist Drill To Process The M2.5 Thread Bottom Hole, And M2.5 Tapping To Process The Thread, Then Change The End Of The Product To Continue Processing.