In the manufacturing industry, the ability to produce high-quality products that meet customers' needs is crucial for success.

This requires the use of reliable, efficient and cost-effective manufacturing processes. Precision die casting is one such process that is widely used to produce complex metal parts with excellent surface finishes and dimensional accuracy.

Precision die casting is a manufacturing process that involves injecting molten metal under high pressure into a steel mold or die. The mold is designed to produce a specific part or component, and the metal is forced into the mold cavity at high speed and pressure. The molten metal then solidifies quickly to form a precise, high-quality part.

Advantages of Precision Die Casting

Precision die casting offers several advantages over other manufacturing processes, including:

1.High Precision: The precision die casting process produces parts with excellent dimensional accuracy, making it ideal for applications where tight tolerances are required.

2.High Strength: Die-cast parts are known for their high strength-to-weight ratio, making them ideal for applications where strength and durability are essential.

3.Excellent Surface Finish: Die-cast parts have a smooth, uniform surface finish that requires little to no post-processing.

4.Versatility: The precision die casting process can be used to produce a wide range of parts in different sizes, shapes, and materials.

5.Cost-Effective: The precision die casting process is a highly efficient and cost-effective way to produce complex metal parts.

Unlocking Optimal Product Performance

Precision die casting parts play a crucial role in unlocking optimal product performance. By producing high-quality, complex metal parts with excellent surface finishes and dimensional accuracy, precision die casting enables manufacturers to produce products that meet or exceed their customers' expectations. This results in products that perform better, last longer, and require less maintenance, providing a significant competitive advantage.

In addition, precision die casting allows manufacturers to design and produce parts that are optimized for performance. By using computer-aided design (CAD) software and simulation tools, manufacturers can optimize the design of die-cast parts to achieve the desired performance characteristics. This can include optimizing the part's geometry, wall thickness, and material properties to ensure optimal strength, durability, and functionality.

Precision die casting is a highly effective manufacturing process that enables manufacturers to produce high-quality, complex metal parts with excellent surface finishes and dimensional accuracy. By unlocking optimal product performance, precision die casting can provide manufacturers with a significant competitive advantage in today's fast-paced, global marketplace. As such, it is a critical process that should be considered by any manufacturer looking to produce high-quality products that meet or exceed their customers' expectations.

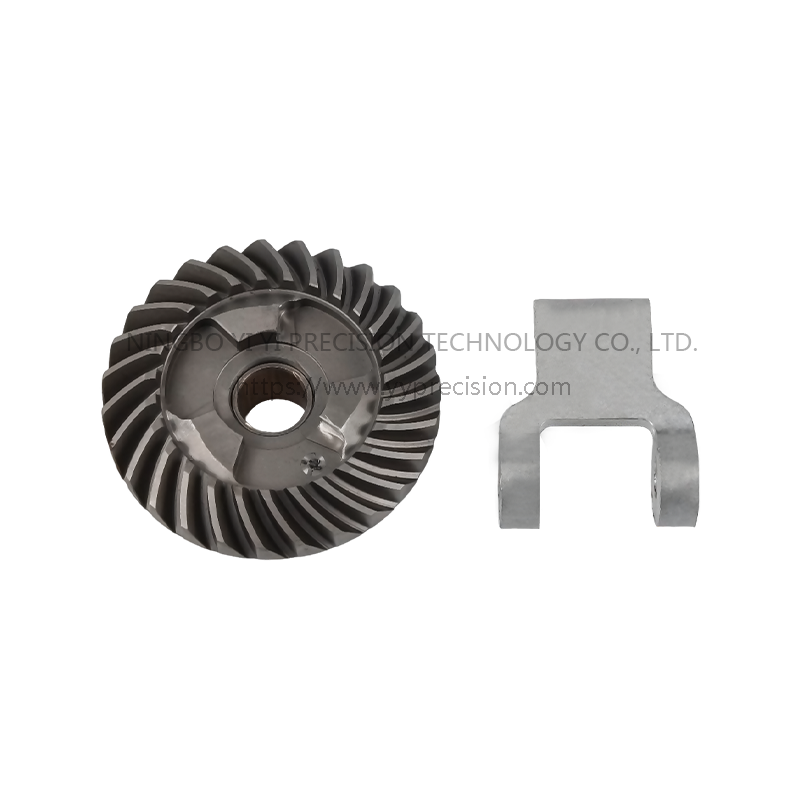

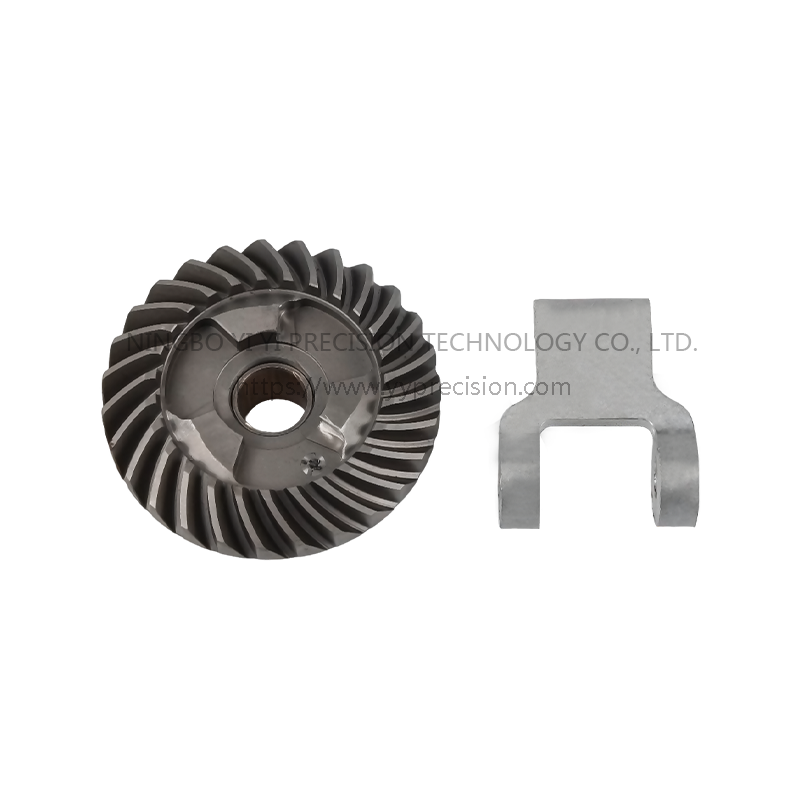

End Gears

Material: SUS304(1.4301)

Number Of Teeth: 26

Outer Diameter: 80