Precision Die Casting Part is an advanced metal processing technology that occupies an important position in the manufacturing industry due to its high precision, high complexity and high performance. The wide application of this technology stems from its unique manufacturing process and superior material properties, making it the first choice for producing high-quality parts in various industries.

Precision die casting far exceeds traditional casting methods in terms of dimensional accuracy. This high precision is reflected in many aspects:

Excellence in dimensional control: In the production process of precision die castings, extremely high dimensional control accuracy can be achieved through strict process control and high-precision mold design. Typically, products can achieve extremely small tolerance ranges and meet stringent industry standards for product accuracy.

Control of shape complexity: Precision die castings not only enable precise control of dimensions, but also enable the manufacture of parts with complex shapes. Its manufacturing process can accurately replicate the complex shapes in the design, including inner cavities, thin-walled structures, etc., ensuring that the product can operate accurately within the design specifications.

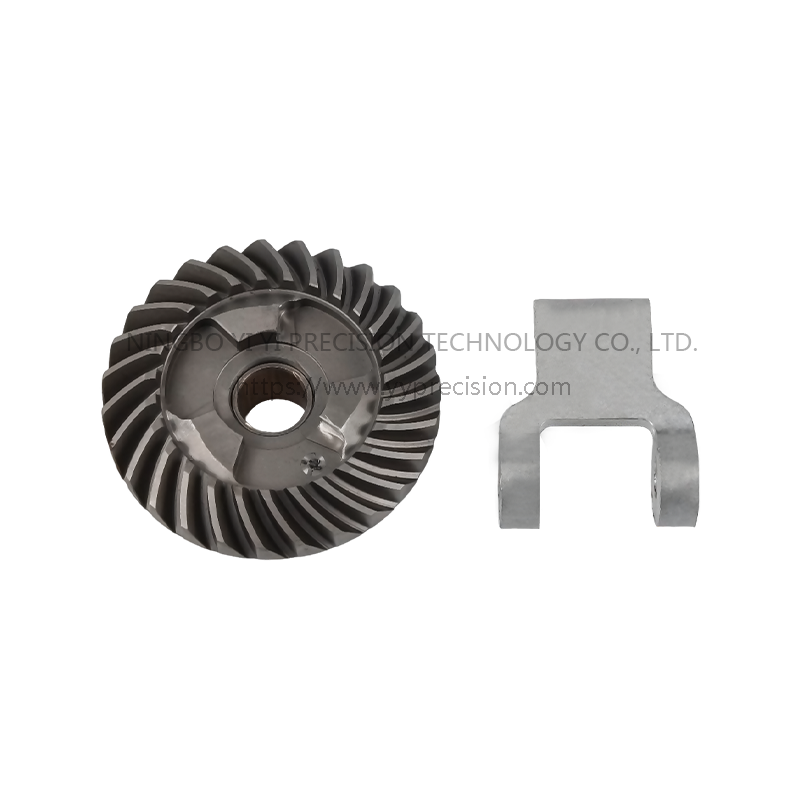

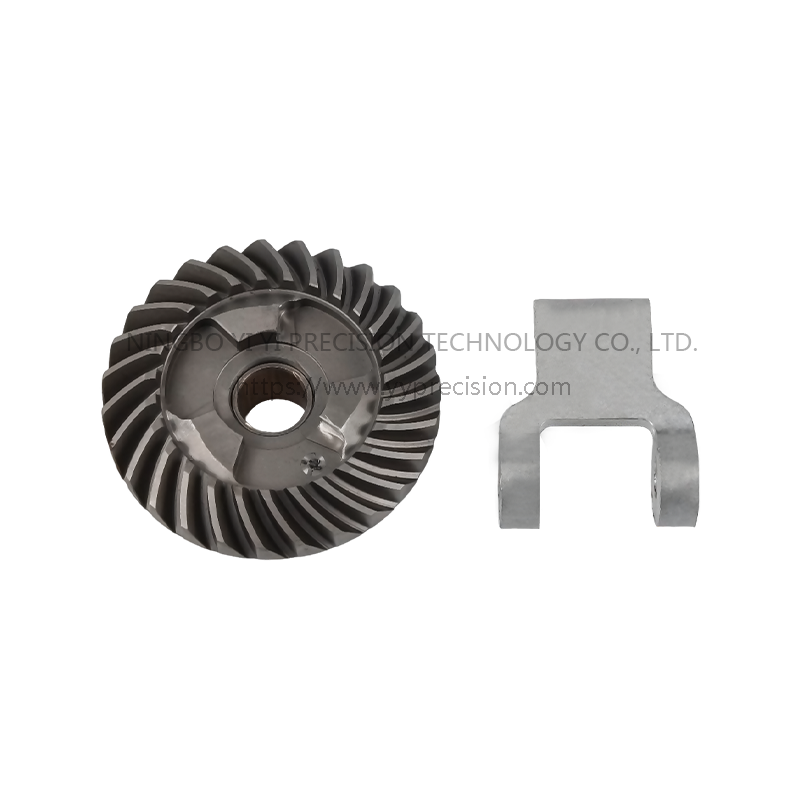

Precision die castings can realize the manufacturing of parts with complex shapes and diverse structures. This high complexity is manifested in the following aspects:

Diversity of structural design: The design of precision die-casting parts is flexible and diverse, and it can realize the manufacturing of parts with various complex structures. Different from traditional processing methods, it can easily handle thin-walled structures, hollow structures, inner cavity structures, etc., and meet the special requirements of different industries for the function and appearance of parts.

Advantages of one-piece molding: Precision die-casting parts usually adopt one-piece molding process, which reduces the connection points of parts, improves the overall strength and stability of the structure, and reduces problems such as air leakage and liquid leakage caused by joints.

Precision die castings are widely used in various industries due to their high performance:

Excellent performance in strength and durability: Excellent precision and material properties give precision die casting products excellent strength and durability. They can withstand harsh working environments such as high pressure and high temperature, ensuring long-term stable operation of the product.

Realization of lightweight design:

Precision Die Casting Parts can often achieve lightweight design, reduce the weight of the entire product, thereby improving the product's fuel economy and transportation efficiency, in line with the requirements of modern industry for energy conservation and emission reduction.

STAINLESS STEEL CASTING

STAINLESS STEEL CASTINGInvestment Casting Process Is Applied. Investment Casting Is Made Of Easy To Burn Material Model, Then Hang Refractory Material On The Model, After Hardening, In The Model Will Be Burned

After Hardening, The Model Is Burned And Discharged From The Model To Obtain A Cast Without Parting Surface, And The Cast Is Poured After Burning.