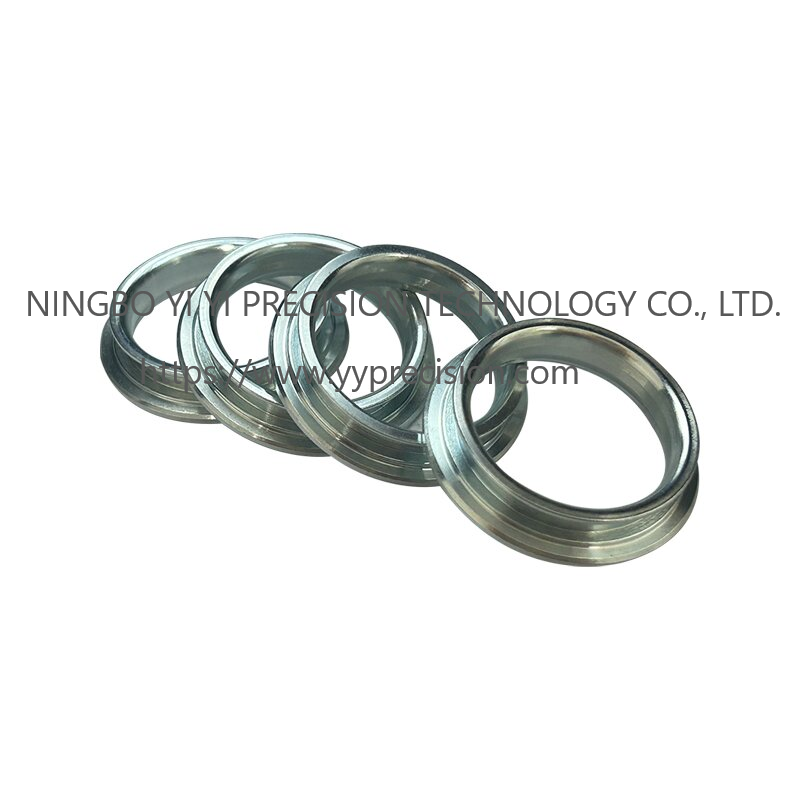

CNC Motor Cover

Material:Turned parts/CNC

1. Customized design: Designed and manufactured according to the unique needs of specific equipment, products or engineering projects, different from standard universal hardware.

2. High precision requirements: there are strict requirements in dimensional accuracy, shape accuracy, position accuracy and surface quality to ensure its performance and reliability in specific applications.

3. Complex processes: It may be necessary to integrate a variety of precision machining processes, such as turning, milling, grinding, EDM, wire cutting, etc., to achieve the required accuracy and shape.

4. Small batch production: Due to its non-standard and customized nature, the production quantity is usually relatively small.

5. High-quality materials: In order to meet the requirements of high performance and high precision, high-quality metal materials are often used, such as high-strength steel, stainless steel, titanium alloy, aluminum alloy, etc.

Non-standard precision hardware is widely used in aerospace, medical equipment, electronic communications, precision instruments, high-end mechanical equipment and other parts of the precision and performance requirements of the field.

Add:No.56 Huanghai Road, Xinqi Street, Beilun District, Ningbo, Zhejiang, China (inside Xingzhi Industrial Park)

Tel:+86-18991368108

Grace@YY-Precision.com

Copyright © Ningbo Yi Yi Precision Technology Co., Ltd.All Rights Reserved

Wholesale Non-standard Precision Turning Parts Manufacturers

Yi Yi

Yi Yi