In the stressful realm of heavy-obligation environments, in which structural integrity and resilience are paramount,

Metal Hexagonal Pillar Screws stand out because the indisputable masters of resistance. These specialised screws are engineered to excel within the face of difficult situations, presenting an remarkable degree of strength and sturdiness that guarantees steadfast performance in critical applications.

The defining function of Metal Hexagonal Pillar Screws lies in their hexagonal layout, which imparts a completely unique gain in phrases of grip and torque. The six-sided shape helps a greater stable and green fastening method, minimizing the danger of slippage or loosening over the years. This attribute is especially essential in heavy-duty environments in which vibrations, excessive temperatures, and high tiers of stress are commonplace.

What units these screws apart is not best their strong construction but additionally the materials from which they are solid. Typically composed of high-grade metals such as stainless-steel or alloy steel, Metal Hexagonal Pillar Screws boast incredible tensile energy and corrosion resistance. This composition ensures that those screws hold their structural integrity even in harsh environments, where exposure to moisture, chemical compounds, or abrasive substances might compromise the efficacy of traditional fasteners.

In heavy-obligation production initiatives, together with the meeting of bridges, skyscrapers, or business equipment, Metal Hexagonal Pillar Screws play a pivotal function in offering the essential stability. The hexagonal form allows for a extra unique and steady in shape, lowering the likelihood of structural failures that might end result from insufficient fastening. This better reliability interprets to increased safety and sturdiness of the structures, assuring stakeholders that their investments are properly-protected against the trials of heavy-responsibility utilization.

The versatility of Metal Hexagonal Pillar Screws extends past traditional construction programs. In manufacturing settings where equipment operates below severe hundreds and situations, these screws function crucial components in securing important additives. Their resistance to fatigue and put on ensures the continuing performance of machinery, contributing to ordinary productivity and minimizing downtime.

These screws are not just components, but also parts.In essential guardians of structural balance and operational reliability in environments wherein most effective the most strong solutions will suffice. As industries keep to push the limits of what is viable,

Metal Hexagonal Pillar Screws stand company as a testomony to engineering excellence, learning resistance and setting a brand new popular for reliability in heavy-duty programs.

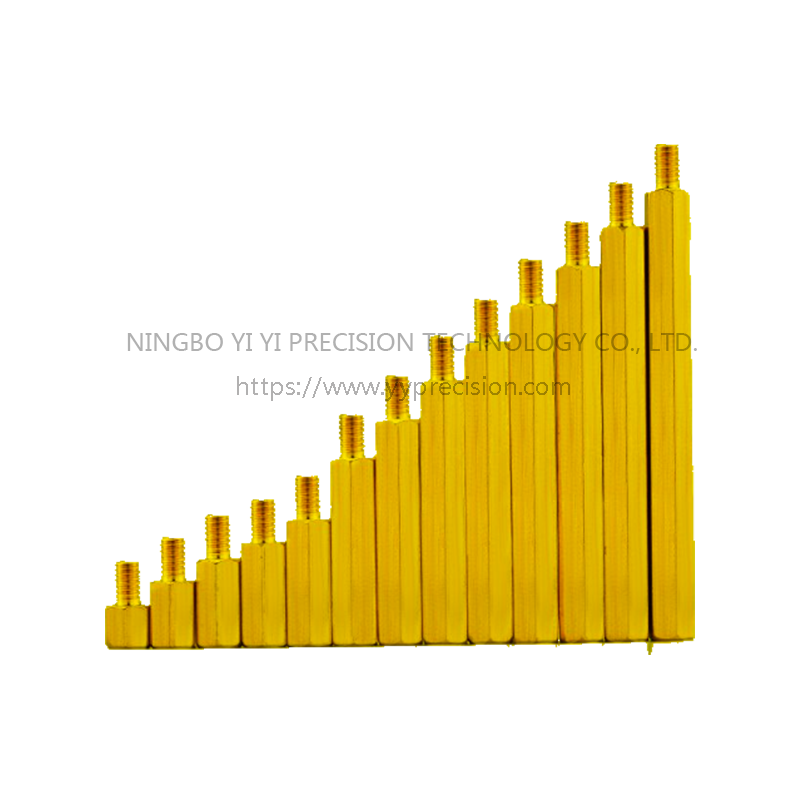

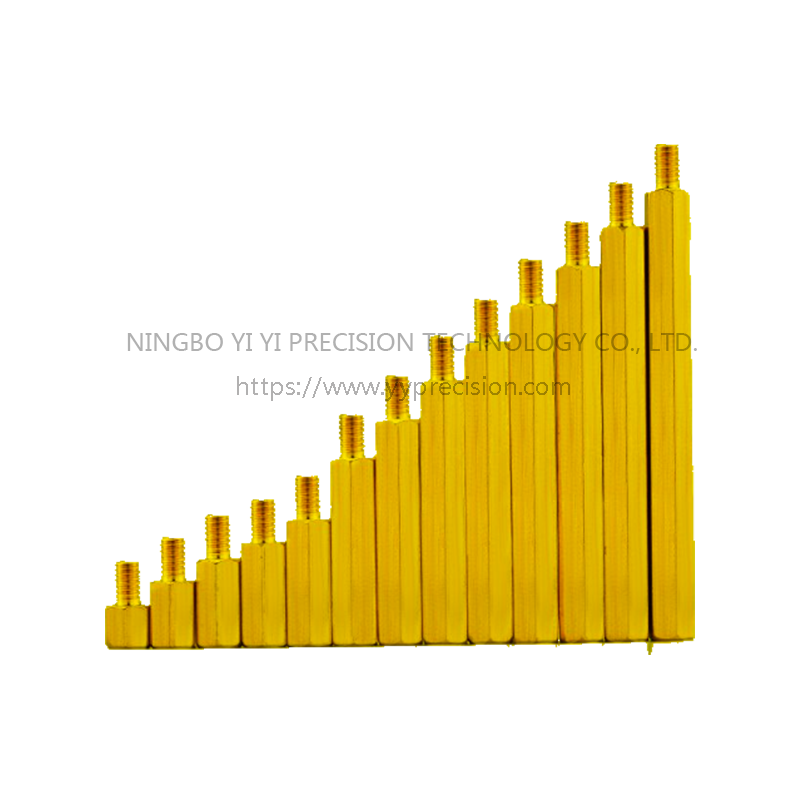

STANDARD HEXAGONAL PILLAR

STANDARD HEXAGONAL PILLAR

Hexagonal Pillar, Also Called Hexagonal Isolation Column, Hexagonal Spacing Column, Hexagonal Support Column, Hexagonal Column, Etc., Plays A Supporting And Connecting Role.

It Is Processed By The STAR Dual-Spindle CNC Centering Machine. First, Use Cylindrical Cutter With 60°R0.4 Corner To Rough The Outer Diameter Of The Thread, And Then Use The Cylindrical Cutter With 35°R0.2 Corner To Finish The Outer Diameter Of The Thread, Use The Thread Cutter To Process The Thread, And Then Use The 35° Cylindrical Cutter And The Thread Cutter To Remove The Thread Burr.