In the world of contemporary manufacturing, these precision-engineered components play a pivotal role in streamlining manufacturing processes, enhancing productiveness, and making sure the manufacturing of wonderful goods.

Stainless Steel Turning Part, a machining manner where a metallic workpiece is turned around and a cutting tool is implemented to shape the material into the desired shape, has come to be a cornerstone within the production enterprise. The use of stainless steel because the number one fabric similarly elevates the performance of this process. Stainless metal is renowned for its fantastic electricity, corrosion resistance, and sturdiness, making it a perfect desire for components that endure the trials of commercial manufacturing.

One of the key advantages of stainless steel turning parts in manufacturing lies in their capacity to face up to harsh situations. The inherent corrosion resistance of stainless-steel guarantees that those additives keep their structural integrity even when uncovered to chemicals, severe temperatures, or abrasive materials. This resilience interprets into a longer lifespan for the equipment and equipment incorporating these turning components, decreasing downtime and maintenance charges.

The precision accomplished through stainless-steel turning contributes to the overall performance of the manufacturing process. The CNC (Computer Numerical Control) technology hired in chrome steel turning lets in for quite accurate and repeatable machining, ensuring that each factor meets stringent excellent standards. This precision is specifically critical in industries wherein tight tolerances and specific specs are non-negotiable, together with aerospace, automobile, and clinical tool manufacturing.

In the context of lean production practices, chrome steel turning components play a essential role in minimizing waste and optimizing useful resource utilization. The performance profits achieved thru unique machining and the sturdiness of stainless-steel make contributions to a discount in fabric waste, electricity consumption, and the need for common replacements. Manufacturers embracing those turning elements discover themselves not most effective improving their environmental footprint but also bolstering their bottom line through cost savings.

The versatility of

stainless steel turning part further enhances their efficiency in manufacturing. These additives locate programs in a wide array of industries, starting from the production of difficult digital gadgets to the introduction of strong additives for heavy machinery. The adaptability of stainless-steel turning allows producers to diversify their product offerings without compromising on exceptional or efficiency.

The usage of stainless steel turning elements in manufacturing represents a paradigm shift closer to heightened efficiency, sturdiness, and precision. As industries evolve and demand for superior merchandise will increase, the role of those turning components turns into more and more integral.

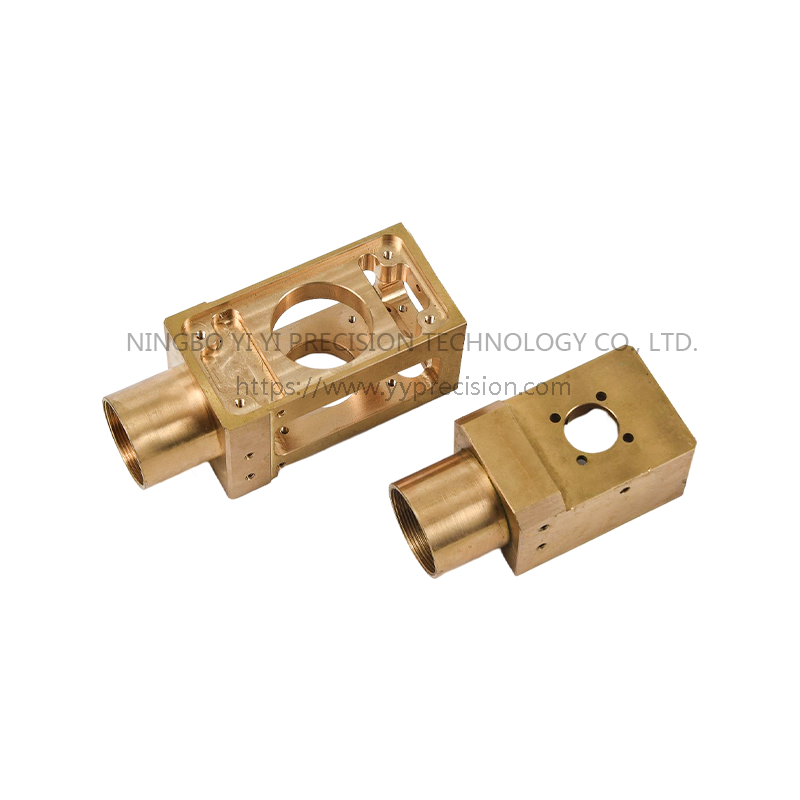

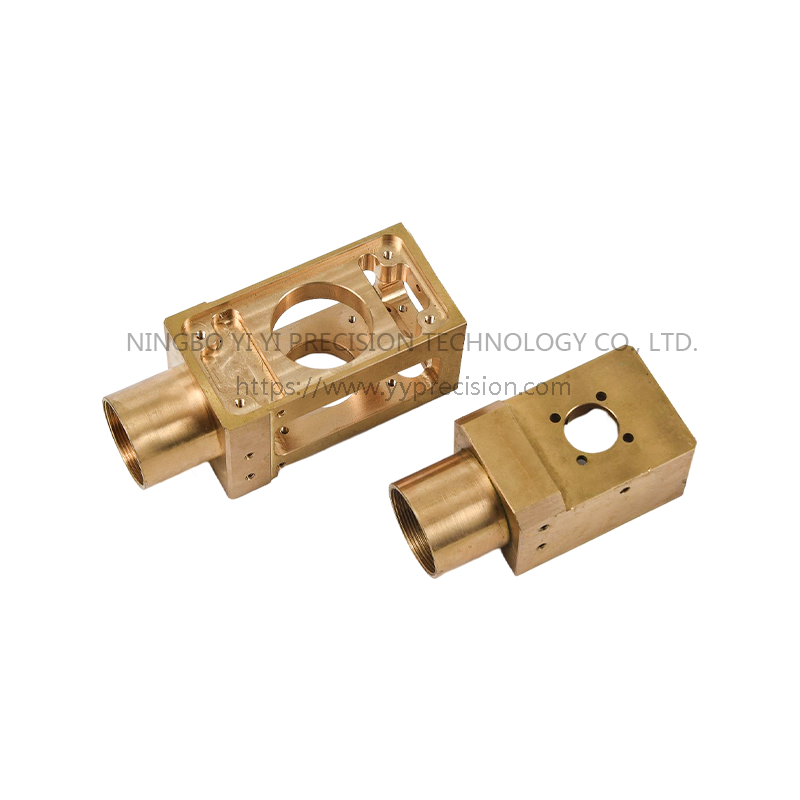

CNC MOTOR MOUNT

CNC MOTOR MOUNTThe Motor Base Is One Of The Important Parts In The Drag Link Of CNC Machine Tools, Using A Large Number Of Small Box-Type Parts, The Main Role Is To Link The Servo Drag Motor And Ball Screw, So The Manufacturing Accuracy Of The Parts, Machining Efficiency Requirements Are Very High.